The main difference is in the design of the press ram.

Standard Portable Compactors (orange compactor in the picture above) have a rectangular-shaped space behind the press ram. As the press ram pushes forward to compact the waste, material slips around the sides and underneath. The material builds up and needs to be cleared out regularly, and at least weekly. It’s a nasty job, particularly with wet waste.

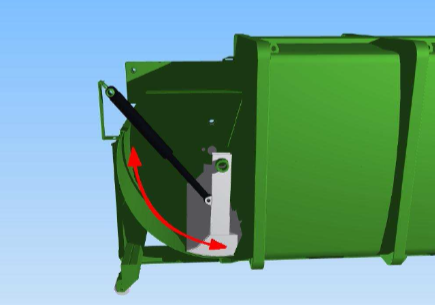

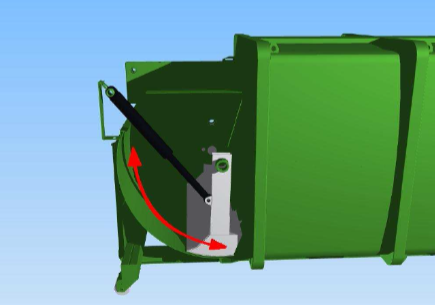

Of course, this cleaning operation is often (usually) not done, resulting in the waste coming into contact with the cylinders which are also in this rectangular space behind the ram, and which is the main functioning part of the machine. Eventually, the cylinders jam up and the machine won’t work (see picture top left). Bergmann Portable Compactors (picture top right) have no rectangular space behind the press ram. The front of the compactor charge box (where the waste is loaded) is curved and the cylinders are radial: the ram pushes the waste around the curved charge box and into the container. Look at this schematic below.

As the cylinder retracts, the rear edge on the reverse of the press ram scrapes any waste which has been loaded or remains in the charge box and deposits it in front of the press ram. When the press ram then moves forward again, this waste is pushed into the container. It is called the 'self-cleaning' blade.

There is no nasty cleaning out to do which keeps maintenance low and the compactor lasts longer. This is a major consideration and needs to be factored in when choosing a new portable compactor: who will manage the weekly cleaning out and what else could they be doing instead? With a Bergmann portable compactor, this is not required.

For more information about Bergmann portable compactors go to our dedicated page: https://www.bergmanndirect.co.uk/waste-compactors/portable Or contact us here.